InverMed use innovative processes in over-moulding, micro moulding, bio-absorbable and specialist tooling and bonding techniques.

1. MOULDING

1.1 INJECTION MOULDING

Injection moulding is the process of polymer materials heated, melted and injected, under high pressure, into a mould, allowed to cool and the product extracted. Different additives can be added to the polymer material to enhance its characteristics.

There are three components to the injection moulding system, the moulding machine, the mould and the material.

Optimising the transfer of the molten polymer into the mould requires specialist knowledge of several areas; including, but not limited to the material, the delivery mechanics and the mould geometry. The combination of relevant skills and attributes is key to successful product moulding

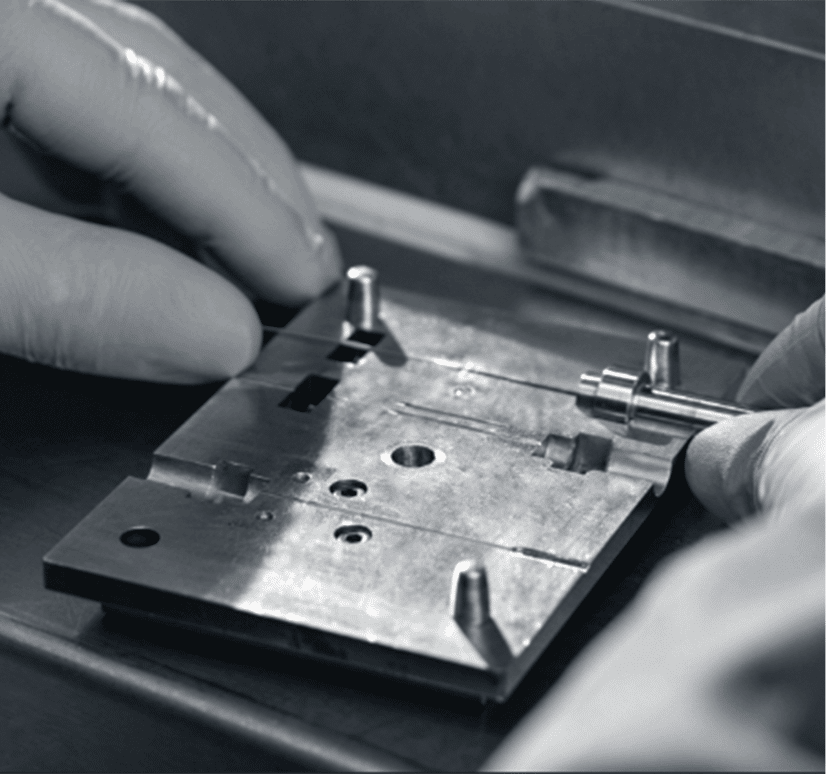

1.2 INSERT MOULDING

Insert moulding involves placing objects or inserts into the mould and moulding polymer around them. This is a very popular process for the medical device industry, as it can often mean disregarding any fasteners or connectors. The part is fully integrated, which leads to increased reliability and extended functionality. Insert molding can be an excellent solution for medical device products with complex final moulded component designs.

1.3 OVER MOULDING

Overmolding is defined as the placing of a previously formed component in an injection molding tool and moulding around it. The part is fully integrated and applications of overmoulding medical devices are limitless. Typically the overmoulding process uses machined metal, injection molded components or extruded components.

InverMed has extensive experience in over-moulding polyimide, polyamide, metal alloy and braided shafts. Achieving strong mechanical locks / high tensile strength demands a combination of feature design, polymer material properties and injection moulding processing.

1.4 MICRO MOULDING

InverMed are the first company in Ireland to offer the use of the Battenfeld micro moulder as a contract service. We can make micro parts, < 0.05gm and lower, in the micro moulder with its own integral cleanroom. Integral to the moulding of micro parts, is the micro tooling. Tolerances of 0.004mm and tighter are achievable. As well as micro tooling and micro moulding, we have also installed specific measurement equipment to complete the micro service.

1.5 BIOABSORBABLE MOULDING

The use of bio-absorbable implants is becoming more and more popular. The moulding of these materials has become possible by the use of precision moulding machines, particularly micro machines as the products are small and the material is expensive. Proper handling of bio-absorbable materials and finished product requires controlled environmental conditions (temperature & relative humidity). The finished product will then be packaged in hermetically-sealed packaging, which has been proven to maintain the integrity and performance of the product.

We have found the ease of bio-absorbable moulding of these materials has greatly improved with experience and know-how and developing processes to handle these materials efficiently. Bio-absorbable materials have been used to support the body while it is healing, so there are lots of possibilities for it’s future in the medical device industry.

2. LOW VOLUME / HIGH VOLUME PRODUCTION

InverMed can support customers’ timelines at all stages of a product’s life cycle. From supply of one-off proof-of-concept models, right through to palletised high-volume product, InverMed has the manufacturing capacity to support rapid and ongoing product growth.

3. PRODUCT ASSEMBLY

Following the manufacture of injection moulded parts, we can assist with the assembly or sub-assembly of component parts. InverMed has the capability to add additional components to a product, this can be done using many different techniques including ultrasonic welding, heat staking and general product assembly.

4. PROCESS AND PRODUCT VALIDATION

Proving the capabilities of a process or a product is essential in demonstrating competence and long-term ability to supply quality product. InverMed have successfully completed many validation projects with several multi-national medical device customers. Our understanding of metrology principles, inspection methods, quality management systems and robust data analysis are applied to ensure satisfactory results. Industry standard software may be used to tailor the validation protocols to match each customer’s specific requirements.

VALUE ADDED SERVICES

InverMed can provide customers with a range of post injection moulding value added services. We have developed many different skill sets and technologies to deliver added value to our customers.

EMI/RFI Shielding

Conductive coatings are functional coatings that are intended for EMI/RFI (Electromagnetic Interference/Radio Frequency Interference) shielding and other applications which require electrical conductivity. They are also used for electrostatic discharge where static grounding is needed. These coatings are generally applied to plastic parts, used in the computer, electronic, and medical fields.

The coating is usually applied to the inside surfaces of an enclosure, creating a Faraday’s cage once the product has been assembled. Copper and silver coated conductive paints are applied with specialized agitated paint spraying equipment. The purpose for the coatings may be for passing UL or FCC requirements, to get the product to market and to meet customer specifications regarding EMI/RFI attenuation.

Pad Printing

Tampo Printing, Pad Printing, and Tampography describe the same method of transferring artwork from a cliché onto a substrate using a silicon pad. A stainless steel cliché is etched with the shape of the artwork design to a depth between 24 to 28 microns. This etched well in the cliché is then flooded with ink. The silicon pad then picks up this thin layer of ink and transfers it onto the substrate.

At InverMed we use this value added process to place company logos, text and numbers onto the product we mould for our customers. This manufacturing process is preferred by our customers, as it gives them the flexibility to change to a different part number within their range without making a change to the mould tool.

Annealing

Annealing is a process by which internal stresses in a moulded part are relieved by heating the part to a specific temperature and cooling at a specific rate. Some polymer materials are prone to “moulded-in stress”, which have been shown to decrease the shelf life of the product.

InverMed provide annealing services to our customers with our Memmert Laboratory oven. This oven has a programmable annealing feature, which allow us to repeatably heat and cool at specific rates.

Surface Treatment via Plasma

Plasma treatments are used to alter the surface properties of a wide range of materials, to make them easier to bond, glue and paint. By treating parts, we both clean and activate the surface, improving their adhesion characteristics. Surface preparation by plasma removes the contaminants from the surface and activates the surface for various applications including improving adhesion and promoting fluid flow.

Ultrasonic Plastics Joining

Ultrasonic welding is a fast, clean and efficient method of assembling plastic mouldings. It is the process of joining or reforming of thermoplastics, through the use of heat generated from high-frequency mechanical motion. It is accomplished by converting high-frequency electrical energy into high-frequency mechanical motion.

Different methods and processes can be used, depending on the moulding and material used. Joining is used to replace or eliminate the need for solvents, adhesives, mechanical fasteners etc.

Hermetically Sealed Packaging

A hermetic seal is a type of sealing that makes a moulded component object airtight and thus prevents the passage of air, oxygen, or other gases that may degrade or break the material down. When processing bioabsorbable polymers, mouldings need to be placed in a hermetically sealed package as soon as they are formed.

A hermetic seal is essential to prevent the loss of electrolyte and corrosion throughout thousands of electrical cycles involving pressure and thermal changes in orbit and during ground storage.

Heat staking

Heat staking is a very effective process used to join metal parts to plastics components. It combines the use of pressure and heat to soften the plastic enough to be remoulded into a new shape or profile, that forms over, or around the connecting part.

UV and Non UV Bonding

UV (Ultraviolet) bonding involves using high-intensity ultraviolet lighting to cure and dry a coating or adhesive. When the UV glue is exposed to this light, a photochemical reaction takes place which causes the glue hardening process. To ensure adequate penetration of the shorter wavelengths of the UV light, at least one of the objects being glued must be transparent.